Eco-Friendly 8/9 Inch Bagasse Pulp 3-Compartment Clamshell Food Container

Product Application

Product Description

U-Yee Pack: Revolutionizing Sustainable Tableware

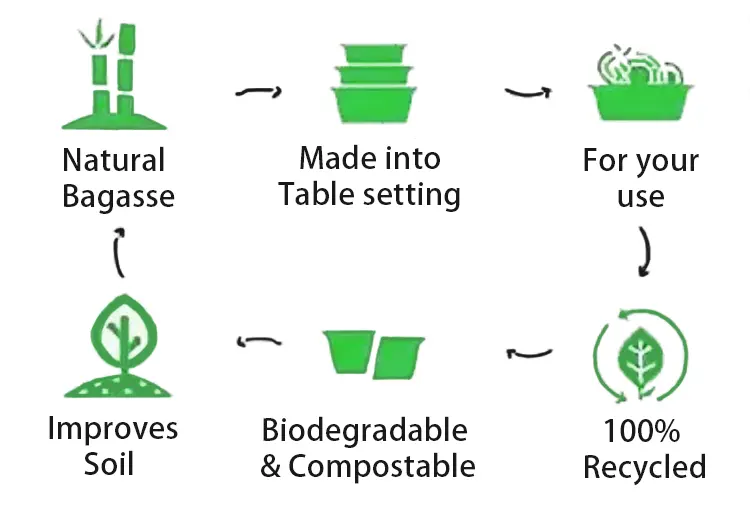

At U-Yee Pack, our mission is to deliver high-quality biodegradable and compostable tableware solutions. By replacing traditional Styrofoam and petroleum-based products with plant-based materials, we offer a sustainable alternative that aligns with global environmental goals.

Bagasse 3-Compartment Clamshell: Key Features

100% Sugarcane Fiber: Made from renewable, biodegradable sugarcane fiber—a sustainable material that supports eco-friendly practices.

Strong & Durable: Designed to withstand everyday use while remaining lightweight and breathable to prevent condensation.

Locking Slot Design: Ensures secure closure for convenient transport during takeout trips.

Microwaveable: Safe for reheating food, with excellent heat retention properties and heat resistance up to 85°C, perfect for serving hot meals.

Heavyweight Material: Protects food from spills or damage during transit, while being stackable for space-saving storage.

Premium Aesthetic: A sleek white finish adds a touch of elegance, making it ideal for restaurants, parties, weddings, BBQs, homes, bars, and more.

No Plastic/Wax Coating: Completely free from plastic or wax coatings, ensuring no harmful residues are left behind after use.

Our bagasse 3-compartment clamshell is not just a product—it’s a commitment to sustainability, quality, and convenience. Perfect for businesses and individuals looking to reduce their carbon footprint without compromising on functionality or style.

Product Characteristics

| Product Name | Bagasse Clamshell | Color | Natural/White |

| Raw Material | 100% Sugarcane/Bagasse Pulp | Size | 450ml/600ml |

| Place of Origin | Guangxi, China | Weight | 15g/20g |

| Packing | Customized Packing | MOQ | 50000pcs |

| Certification | CLFGB | Lead Time | 30 days or negotiated |

Packaging/Shipping

Initial Packaging

Neat Arrangement

Loading Process

Final Check

First, the bagasse products completed on the production line are initially packaged, and each bagasse product is individually wrapped in a high quality waterproof plastic bag. The bagasse products, wrapped in waterproof plastic bags, are then neatly arranged and placed in sturdy cartons. These cartons are often custom-designed to fit the product size to ensure maximum internal space utilization while providing adequate protection. When all bagasse products have been properly placed in cartons, the staff will load the cartons full of products onto the truck in accordance with the established stacking rules. After all predetermined quantities of bagasse products have been successfully loaded into the truck, the final step is to check that all goods are secure, cover them with tarpaulins to protect them from the elements, and ensure that the relevant transportation documents are in order. Once confirmed, you can close the door and prepare to leave for your destination