Biodegradable 10-Inch Sugarcane Bagasse Oval Plate – Eco-Friendly Disposable Serving Plate for Food Service & Catering

Custom Packing Method

Heat shrink (tight wrap)

Heat shrink (loose wrap) with label

Seal wrap with label

Loose wrap with label

Eco-Friendly Sugarcane Bagasse Plates – Microwave & Freezer Safe | Heat Resistant Up to 220°FOur sugarcane bagasse plates are a sustainable, compostable alternative to traditional disposable tableware. Available in multiple sizes—including our popular 10-inch round sugarcane plate—they are ideal for both hot and cold foods, and are designed to meet the demands of food service, catering, and retail environments.

Key Features

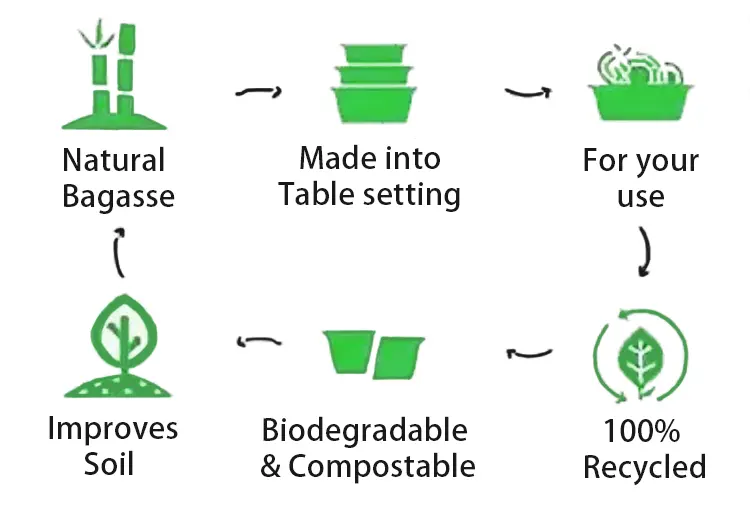

1. Made from 100% Natural Sugarcane Fiber (Bagasse)

2.100% biodegradable and compostable

3. No bleaching agents used — retains the natural color and texture of plant fiber

4. Non-toxic, clean, and food-safe

Microwave & Freezer Safe

1. Heat resistant up to 220°F – perfect for reheating meals

2. Can be stored in freezers to keep food fresh

3. Suitable for serving hot dishes, soups, sauces, and cold meals alike

Durable & Leak-Proof Design

1. Strong structure that resists breaking or cracking under pressure

2. Smooth edges and excellent craftsmanship

3. Knife-scratch and puncture-resistant surface

4. Liquid-proof lining ensures no leaks or spills

Multi-Functional & Versatile

1. Ideal for restaurants, cafes, catering services, and takeout businesses

2. Great for outdoor events, picnics, and home use

3. Available in various sizes and styles (square, round, oval)

Environmentally Responsible Manufacturing

1. Made from agricultural byproduct (bagasse) that would otherwise be burned

2. Reduces reliance on wood-based paper products

3. 3.Prevents air pollution by repurposing waste into useful, eco-friendly products

4.Request a FREE sample today and experience the quality and sustainability of our sugarcane tableware firsthand!

Product Characteristics

|

Product Name |

bagasse plates |

Color |

Natural/White |

|

Raw Material |

100% Sugarcane/Bagasse Pulp |

Certification |

LFGB |

|

Place of Origin |

Guangxi, China |

Packing |

Customized Packing |

|

Size |

450ml/600ml |

MOQ |

50000pcs |

|

Weight |

7g |

Lead Time |

30 days or negotiated |

Packaging/Shipping

Initial Packaging

Neat Arrangement

Loading Process

Final Check

First, the bagasse products completed on the production line are initially packaged, and each bagasse product is individually wrapped in a high quality waterproof plastic bag. The bagasse products, wrapped in waterproof plastic bags, are then neatly arranged and placed in sturdy cartons. These cartons are often custom-designed to fit the product size to ensure maximum internal space utilization while providing adequate protection. When all bagasse products have been properly placed in cartons, the staff will load the cartons full of products onto the truck in accordance with the established stacking rules. After all predetermined quantities of bagasse products have been successfully loaded into the truck, the final step is to check that all goods are secure, cover them with tarpaulins to protect them from the elements, and ensure that the relevant transportation documents are in order. Once confirmed, you can close the door and prepare to leave for your destination